Kitchen Hood Fire Suppression System Inspections in New York, New Jersey, and Long Island

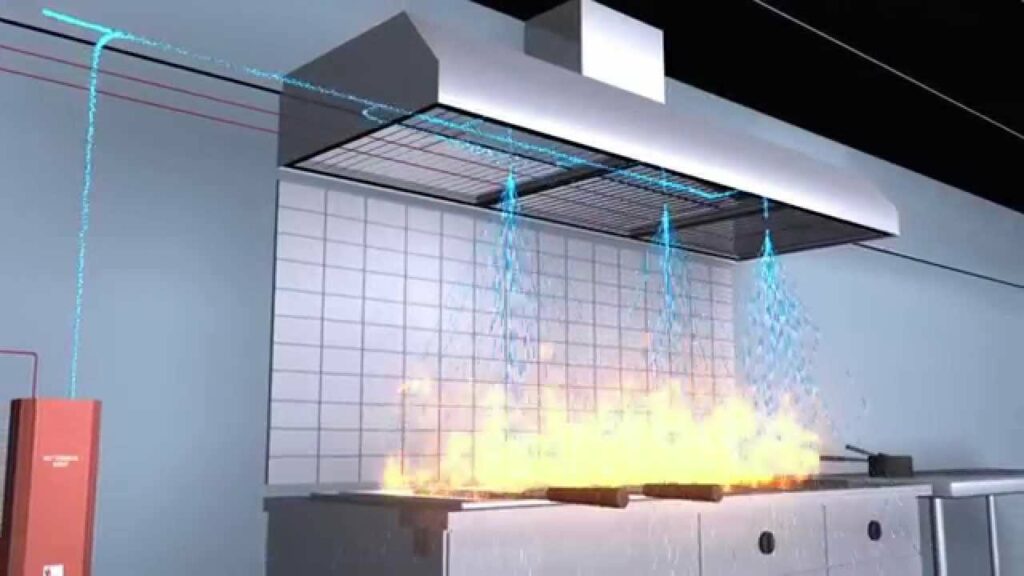

A kitchen hood fire suppression system inspection focuses on critical components such as nozzles, fusible links, and pressure gauges. These parts must be checked for grease buildup or any signs of damage that could prevent proper system activation. According to NFPA 96, hood systems in any commercial kitchen require frequent maintenance to comply with local fire code regulations. A thorough check ensures the extinguishing agent is ready for immediate action if a restaurant fire occurs.

— Kitchen Fire Suppression Inspection in New York

Regular Kitchen Fire Suppression System Inspections for Fire Safety

Routine kitchen fire suppression system inspections are crucial for fire safety. In fact, many authorities require a semi-annual inspection to ensure all extinguishing systems remain in top condition. During these visits, a certified technician performs a visual inspection of each component—checking tamper indicators, evaluating on-site fire extinguishers, and verifying that fire protection systems align with national fire protection association guidelines. This approach safeguards life safety and helps your licensed fire protection company provide comprehensive fire protection.

At Chase Fire, we understand the importance of keeping your commercial kitchen safe and up to code. One critical aspect is performing regular kitchen hood fire suppression system inspection services to ensure everything remains in working order. When you prioritize these inspections, you help protect your staff, customers, and property from unexpected fire hazards.

Frequently Asked Questions

Per NFPA 96 and local fire code requirements, it’s recommended to schedule a semi-annual inspection—every six months. This ensures your kitchen fire suppression system remains in working order, reducing the risk of a restaurant fire and keeping your cooking equipment protected.

Testing involves more than pulling a lever. A certified technician performs a visual inspection of system components, checks for grease buildup or clogged nozzles, confirms tamper indicators are intact, and verifies system activation in coordination with your gas shut-off and fire alarm. Because test procedures vary by system designs, it’s best to rely on a licensed fire protection company with the right experience.

A kitchen hood fire suppression system inspection is a thorough review of all safety mechanisms that protect your commercial kitchen. It typically includes checking the extinguishing agent, fusible links, pressure gauges, pull station, and overall fire protection readiness. Inspectors also ensure there’s no buildup in your exhaust system that could hinder fire safety.

The national fire protection association (specifically NFPA 96) sets the primary standards. Local New York fire department regulations also apply, so it’s vital to adhere to both sets of rules. Staying compliant helps ensure life safety and prevents potential shutdowns due to violations of fire code.

If you can’t recall or it’s been more than six months, you might be out of compliance. Frequent kitchen fire suppression system inspections not only keep you code-compliant but also protect your business from costly fire hazards. Check the inspection tag if it's on the bottle or pull of the suppression system.

Absolutely. At Chase Fire, our fire protection services include on-site evaluations and inspection report documentation to help you maintain a safe, compliant operation. As a licensed fire protection company, we have the knowledge and expertise to keep your system up to date.

Before a visual inspection, clear away clutter under the hood area and ensure all cooking equipment is turned off. Make sure there’s no excessive grease buildup around the exhaust system. Providing easy access to the hood, nozzles, and pull station streamlines the inspection process.

Yes. If your commercial kitchen fire suppression system discharges (whether by accident or during a restaurant fire), it typically requires manual resetting. A certified technician will replace any spent extinguishing agent, reset the control panel if needed, and verify that everything is back in working order.

Frequent problems include clogged nozzles, worn fusible links, damage to blow-off caps, and internal grease buildup in the hood or ductwork. These issues can delay system activation and compromise fire safety, which is why routine checks are so important.

Inspections verify each component of your extinguishing systems:

- Visual inspection of pressure gauges, piping, tamper indicators, and the hood area

- Confirmation that the extinguishing agent meets the proper levels

- Ensuring gas shut-off devices operate correctly

- Checking the pull station for functionality

- Reviewing alignment with fire code and national fire protection association standards

- System Shutdown: Temporarily power down fans and equipment.

- Hood & Duct Check: Inspect the exhaust system for any grease buildup.

- Nozzle & Fusible Links Assessment: Confirm alignment, cleanliness, and proper functioning.

- Agent Tank & Pressure Gauges: Ensure correct pressure readings and extinguishing agent levels.

- Reset & Final Verification: Reactivate the system and test fire alarm integration.

By following these steps, a certified technician helps keep your kitchen hood fire suppression system in prime condition, meeting all fire protection standards in New York and beyond.

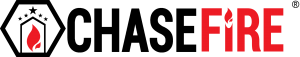

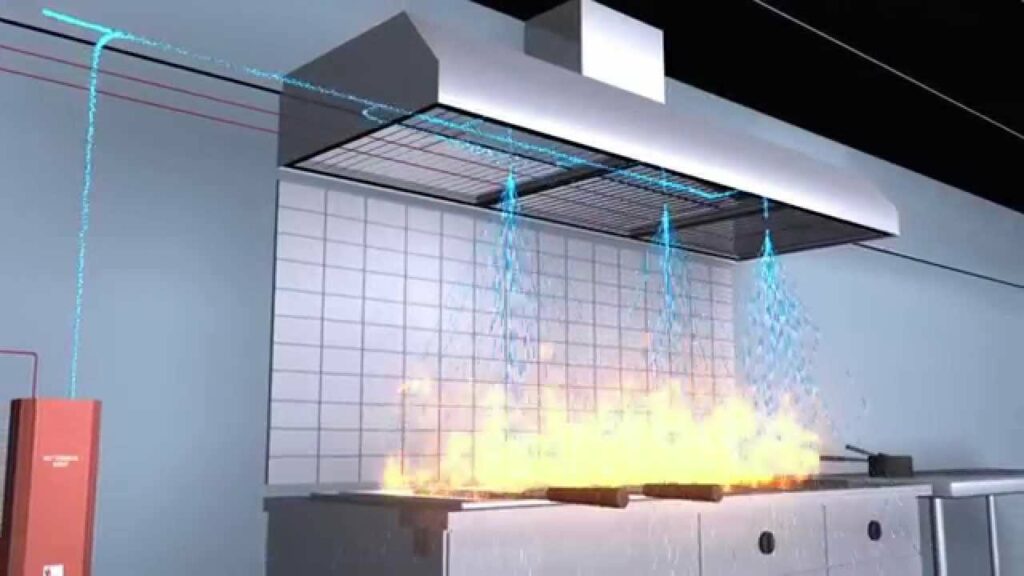

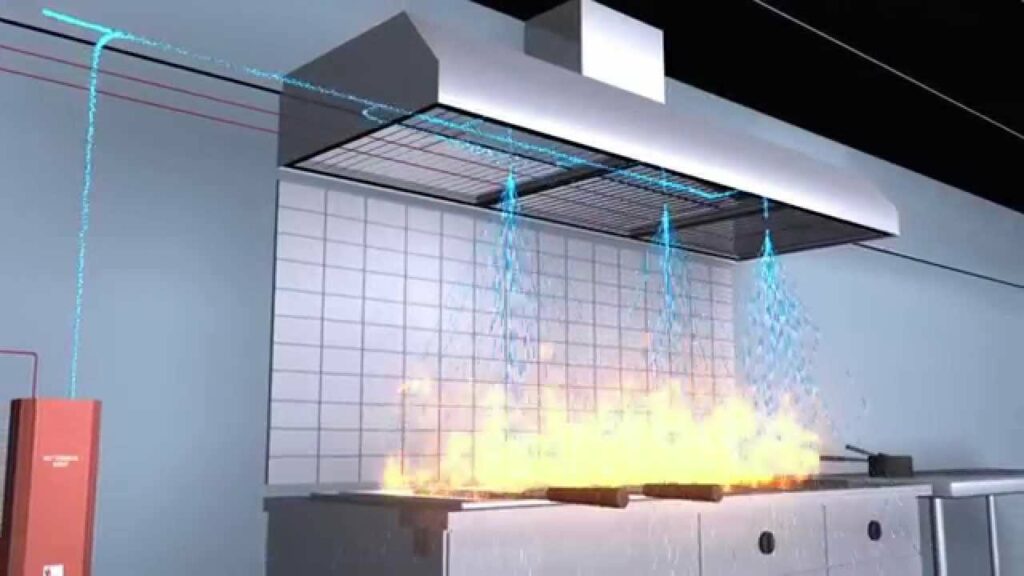

Why You Need a Commercial Kitchen Fire Suppression System

A commercial kitchen fire suppression system effectively prevents flames from spreading across cooking equipment. Quickly releasing a wet chemical extinguishing solution smothers flames and helps avoid severe damage. When properly installed and maintained, these systems lower the risk of restaurant fire incidents that could disrupt business operations. Additionally, they integrate seamlessly with your fire alarm and gas shut-off features, ensuring a swift response in emergencies.

Proper placement of the system (location) offering clear access.

Pressure gauges are within effective range.

Location of manual pull station actuators is easily visible and unobstructed.

Portable fire extinguishers are intact, sealed, charged, wall-mounted and nearby cooking appliances.

Maintenance certificate/tag is in place and visible; tamper indicators and seals are intact.

There is no physical damage to the system that is visible to the eye.

Nozzle blowoff caps are neither broken nor damaged. Their nozzles must also face the center of the cooking appliance that the owner wants to shield from fire damage.

The cooking appliances that are to be protected from fire damage, as well as hoods and ducts, should not have been replaced, moved or modified following installation.

Extinguishing Systems for Restaurant Fire Hazards

Modern system designs incorporate specialized nozzles that target specific fire-prone areas, reducing the chance of buildup around the exhaust system. Different extinguishing systems can include wet chemical solutions or other agents, each designed to combat various fire hazards. A proper visual inspection ensures these features remain operational, especially in high-heat environments where fire sprinkler coverage may not reach every surface.

Fire Protection Upgrades and Fire Sprinkler Integration

Beyond hood-based solutions, integrating a fire sprinkler system can vastly improve overall fire protection services in your establishment. Sprinklers complement fire extinguisher inspection schedules and on-site testing, ensuring every corner of your commercial kitchen meets the highest safety standards. Regular evaluations also confirm that system activation triggers correctly, aligning with national fire protection association criteria.

Schedule Your Next Inspection with Chase Fire

After each semi-annual inspection, our licensed fire protection company issues a detailed inspection report verifying that all blow-off caps are intact and your system is in working order. We also confirm the pull station functionality, ensuring staff can manually release the system if needed. Additionally, we coordinate with the local fire department to confirm compliance with the latest fire code requirements. Our certified technician will test your exhaust system and clear any grease buildup that could compromise performance. By taking these steps, we help ensure your kitchen meets essential life safety standards and remains fully protected.

Contact Chase Fire Today

Don’t wait until a small flare-up becomes a major restaurant fire emergency. Get in touch with Chase Fire to schedule your kitchen hood fire suppression system inspection and keep your operation protected. We’re here to help you maintain a safe, compliant environment for everyone involved.